Quality first

TIME:2021-11-03 SOURCE:胜狮能源

Some people say that October is the season of late autumn, and the grass and trees are sparse, which is easy to make people sad. It is also said that October is the harvest season, and the golden autumn in October is fruitful. But I am here to say that October is a season for quality to take off. Let us work hard for it, strive for it, and persevere.

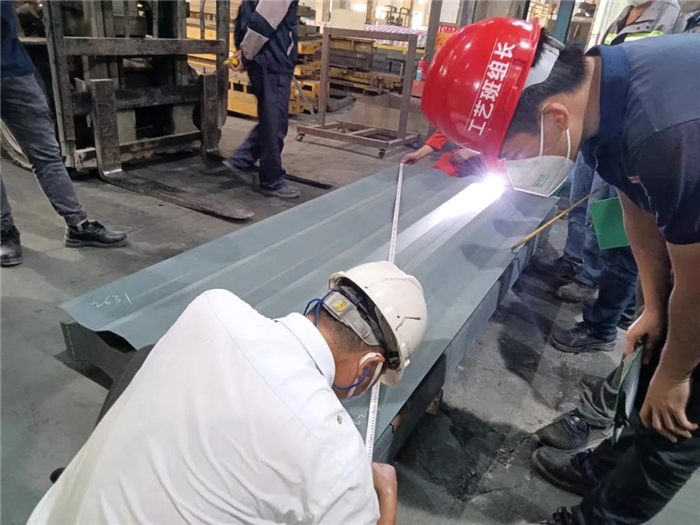

The quality activity month kicked off in the warm sun in October.

The quality activity month kicked off in the warm sun in October.

The publicity of quality must be thorough

There is no doubt that the survival of enterprises must rely on excellent quality to meet the needs of customers and obtain corresponding orders. In other words, quality is the blood, life and powerful competitive weapon of an enterprise.

At the regular morning meeting and evening party, the team leader conveyed the quality requirements of each batch of boxes and the key points of customers. The cool morning breeze blows the quality of the October activity month and burns into every operator's heart, imperceptibly turning into a normal state.

"Pay more attention to production and fewer quality problems"

"I would rather check in advance than rework afterwards"

"Implement self inspection and mutual inspection to ensure zero defects of products"

"Everyone participates in quality, everyone practices quality, and everyone supervises quality"

When these easy to understand but thought-provoking words appear in every corner of the workshop, they are not only slogans, but also slogans. They are a kind of responsibility, a kind of responsibility, and a kind of reflection in mind.

The role of quality system is prevention, and quality improvement is not once and for all

Through prevention to produce quality, don't waste time on finding and repairing, and the most basic thing of prevention is that we must do the product well in the first time according to the process specifications, operation instructions, inspection standards, and whether the size, angle, or assembly must meet the process requirements and customer requirements.

The focus of quality control should be placed on the manufacturing stage, rather than the subsequent process to check and make up for omissions, otherwise it will lead to high cost and low efficiency. All staff shall participate in quality control, eliminate bad operation and implement it. Quality does not come from inspection, but from process prevention and improvement. Preventing quality accidents can make our efficiency get twice the result with half the effort.

Quality activity month is an entry point. We must form an inherent quality concept and integrate it into our blood. The inspection itself cannot improve the quality, nor can it fully guarantee the quality, improve the unreasonable parts of the production system, and carry out process control. Establishment of error proofing device, such as corner assembly; Hardware facilities, such as door frame assembly; These are the places where the head of the stage and relevant managers think and improve.

Quality improvement is not once and for all, it must be adhered to for a long time.

There is no doubt that the survival of enterprises must rely on excellent quality to meet the needs of customers and obtain corresponding orders. In other words, quality is the blood, life and powerful competitive weapon of an enterprise.

At the regular morning meeting and evening party, the team leader conveyed the quality requirements of each batch of boxes and the key points of customers. The cool morning breeze blows the quality of the October activity month and burns into every operator's heart, imperceptibly turning into a normal state.

"Pay more attention to production and fewer quality problems"

"I would rather check in advance than rework afterwards"

"Implement self inspection and mutual inspection to ensure zero defects of products"

"Everyone participates in quality, everyone practices quality, and everyone supervises quality"

When these easy to understand but thought-provoking words appear in every corner of the workshop, they are not only slogans, but also slogans. They are a kind of responsibility, a kind of responsibility, and a kind of reflection in mind.

The role of quality system is prevention, and quality improvement is not once and for all

Through prevention to produce quality, don't waste time on finding and repairing, and the most basic thing of prevention is that we must do the product well in the first time according to the process specifications, operation instructions, inspection standards, and whether the size, angle, or assembly must meet the process requirements and customer requirements.

The focus of quality control should be placed on the manufacturing stage, rather than the subsequent process to check and make up for omissions, otherwise it will lead to high cost and low efficiency. All staff shall participate in quality control, eliminate bad operation and implement it. Quality does not come from inspection, but from process prevention and improvement. Preventing quality accidents can make our efficiency get twice the result with half the effort.

Quality activity month is an entry point. We must form an inherent quality concept and integrate it into our blood. The inspection itself cannot improve the quality, nor can it fully guarantee the quality, improve the unreasonable parts of the production system, and carry out process control. Establishment of error proofing device, such as corner assembly; Hardware facilities, such as door frame assembly; These are the places where the head of the stage and relevant managers think and improve.

Quality improvement is not once and for all, it must be adhered to for a long time.